Electrical junction boxes function as protected connection points within electrical and control systems. Their structural design, material composition, ingress protection capability, and mounting configuration directly influence reliability, service life, and maintenance efficiency. For engineers engaged in system integration, enclosure design and component selection must follow both electrical safety fundamentals and real-world performance requirements.

At Hofengfab, we design and manufacture junction boxes in metal and engineering-grade polymers, supporting custom enclosure geometries, mounting layouts, sealing grades, and machining requirements for OEM and industrial applications.

1. Core Design Principles

Regardless of application category, the following fundamentals apply:

-

Protected Conductor Termination

All splices, terminal blocks, or bus connectors must be enclosed to prevent accidental contact, dust ingress, moisture exposure, and mechanical stress. -

Service Accessibility

The junction box cover must allow reversible access for inspection, torque verification, and re-termination. Permanent sealing is only acceptable in IP-specific conditions such as outdoor sealed installations. -

Volume-to-Wiring Density Ratio

Cable bend radius and heat dissipation are impacted by internal space. Under-sizing leads to conductor stress and elevated temperature gradients. -

Cable Entry Management

Cable glands, compression fittings, or molded entry knockouts are required to ensure strain relief and maintain enclosure integrity under vibration or environmental cycling. -

Environmental Compatibility

Outdoor and industrial conditions may require UV-resistant polymers, corrosion-resistant metals, or high-seal gaskets compliant with IP65 / IP66 / IP67 depending on project specifications.

2. Common Types of Junction Boxes

Different applications require different enclosure designs. Some widely used types include:

| Type | Description | Common Use Cases |

|---|---|---|

| Wall Junction Box | Mounted on walls or panels | Building wiring, machinery interfaces |

| Plastic Electrical Boxes | Lightweight, corrosion-resistant, cost-effective | Indoor wiring, low-voltage projects |

| Metal Junction Boxes | High strength, heat-resistant, suitable for industrial settings | Factory equipment, power distribution |

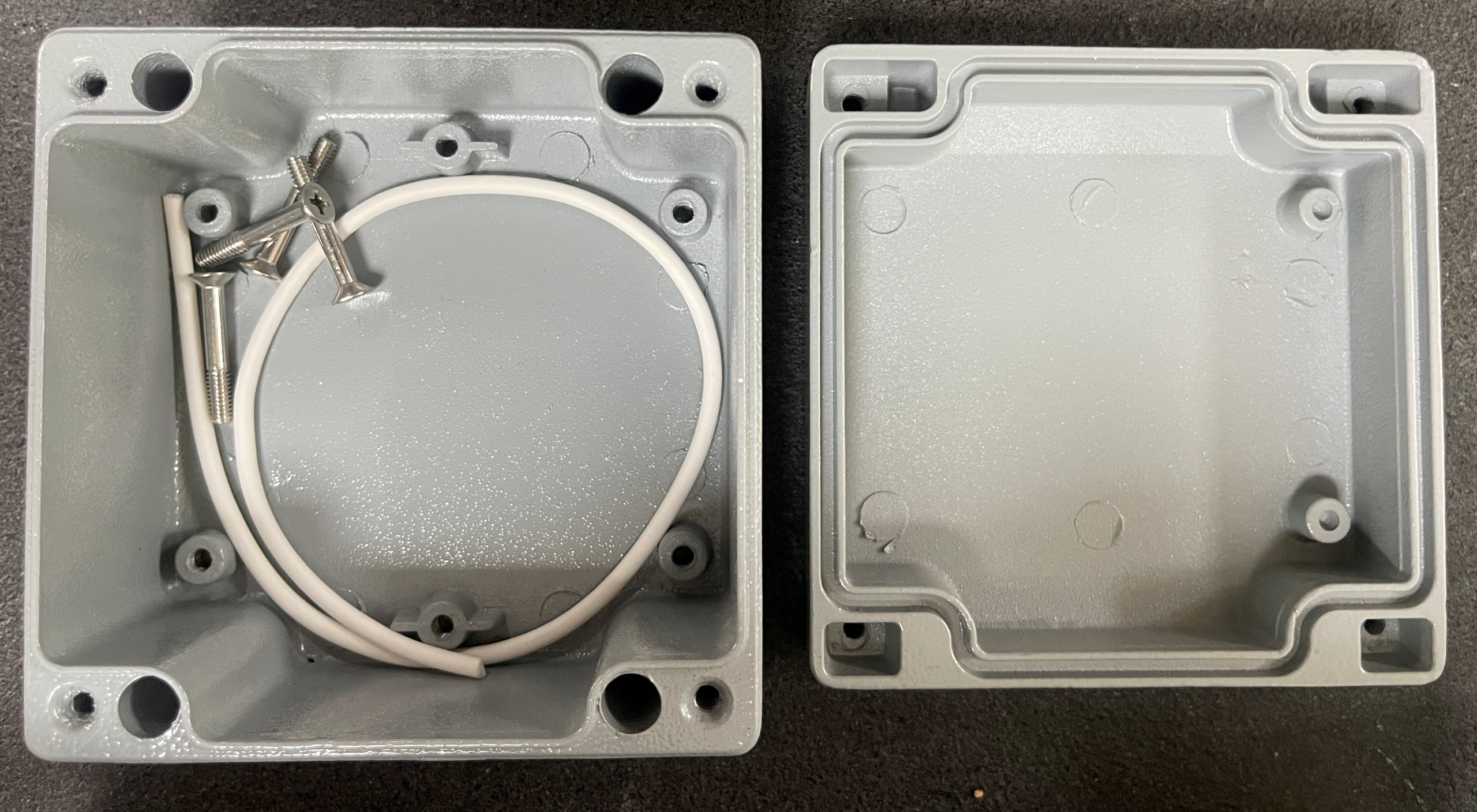

| Junction Box with Cover | Includes a removable lid for inspection and protection | General wiring connections |

| Outdoor Junction Box / Waterproof Junction Box | Sealed design with gaskets, rated for moisture & dust protection | Solar systems, exterior lighting, marine environments |

At Hofengfab, we support custom material options such as ABS, PC, stainless steel, and aluminum alloy, depending on durability and environmental requirements.

3. Structural & Mounting Variants

-

Wall Junction Box: Surface-mount, used for distributed wiring nodes and equipment I/O interfaces.

-

DIN-Rail Compartment: Used for control modules, relay banks, and PLC terminal blocks.

-

Pole / Field Mount Outdoor Junction Box: Typically paired with gaskets, stainless fasteners, and reinforced cable entries.

-

Sealed Waterproof Junction Box: Used for solar PV, telecom towers, marine lighting, and remote sensing nodes.

Hofengfab supports:

-

Internal rail mounting plates

-

Custom bracket geometry

-

Threaded inserts / PEM hardware

-

Knockout punch patterns for field wiring

4. How to Select the Right Junction Box

Choosing the correct enclosure involves evaluating both the installation environment and performance expectations:

-

Indoor or Outdoor

Outdoor installations may need waterproof sealing, corrosion-resistant materials, and UV-stable housing. -

Plastic vs Metal

-

Plastic electrical boxes → lightweight, non-conductive, affordable.

-

Metal junction boxes → robust, heat-dissipating, suitable for heavy-duty applications.

-

-

Size and Wiring Space

Consider the number of cables, connectors, and any future expansion. -

Mounting Requirements

Wall mounting, surface mounting, DIN rail mounting, pole mounting — we can supply all configurations. -

Aesthetic and Branding Needs

For OEM projects, we offer surface finishing, logo engraving, and customized colors.

5. Engineering Support from Hofengfab

We provide:

-

Custom enclosure mechanical design (CNC, sheet metal, injection molded parts)

-

Rapid prototyping for field testing

-

Material selection guidance based on load, temperature, and exposure

-

Batch production with configurable hardware and branding

-

Export packaging suitable for industrial deployment

Our manufacturing is optimized for:

-

Industrial automation OEMs

-

Renewable energy system integrators

-

Smart device and sensor manufacturers

If you are seeking custom-designed junction boxes for your upcoming project, Hofengfab can provide engineering support, prototyping, and scalable production to meet your requirements.